One of the safest and most efficient ways to move pallets of product around a factory or warehouse is to utilise an automated pallet conveyor solution. If pallet conveyors are not utilised then often the only other way of moving pallets around is via forklift trucks.

So why use conveyors over forklifts?

1.jpg)

Moving pallets around a warehouse or factory from one area, say production, to the dispatch area can be a very labour intensive process. Couple these labour costs with the costs of purchasing/leasing and maintaining the vehicles and the costs can mount up.

Then you have the possibility of human error coming into the mix. Nobody is perfect and humans make mistakes, mistakes on a forklift with a pallet of product can be a dangerous thing leading to the possibility of injury, damaged or ruined product and damage to other equipment.

Conveyors not only give you the ability to safely transport your pallets they also give you somewhere to store pallets until you are ready to move them on. Frequently Advance install pallet handling systems that allow pallet accumulation, that way pallets can be loaded at one end and accumulate at a dispatch area ready for shipping.

More and more companies are getting in touch with us to discuss ways to reduce the amount of forklift traffic they have around their factory or warehouse. One of the most efficient ways of doing this is to install an automated pallet handling conveyor system.

How much will a pallet handling system cost me?

This very much depends on how automated you want to be, what you are carrying and how far you need to transport it. Get in touch with us today to discuss your options.

Pallet conveyor systems can start out very basic, with their only function to move pallets from point A to point B in a straight line. Either through powered conveyors or gravity (unpowered) conveyors.

At the other end of the scale are the fully automated pallet conveyor systems which need to carry out a number of functions whilst navigating pallets round a large warehouse or factory. These systems can contain things like:

- Full system accumulation. Our SmartLine pallet handling conveyor can be manufactured to allow for full accumulation along the entire system. With the conveyor split into individually driven zones, driven with either Lenze smart motors or Interroll pallet drives, it is a very energy efficient method of creating a buffer storage of palletised product.

- Pallet wrapping and labelling. Want to automate the wrapping and labelling of your pallets? Not a problem, Advance can manufacture pallet lines with inline, fully automatic, pallet wrappers and pallet labellers from top manufacturers.

- Robotic palletisation. To fully automate the palletisation side of your business then consider utilising a robot to palletise the product too. Advance can offer tailormade solutions to delivery your boxed/bagged etc. product to a robot, have that robot pack the product onto a pallet and move the pallet away once full. Delivering an empty pallet to the robot in the process.

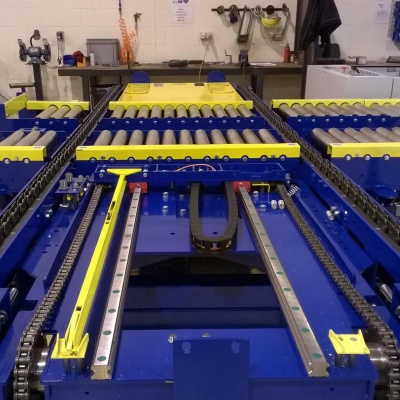

- Turntables and transfers. It is rare that you will get away with moving your pallet from where you have it to where you need it by going in a completely straight line. More than likely you are going to have many changes in direction in the route and so to achieve this Advance manufacture automated turntable units and chain cross transfers. All as part of the standard SmartLine range.

- Lifts and elevators. Need to get your pallets up to or down from a mezzanine floor? Utilise a pallet lift to avoid having to lift off with a forklift. Pallet lifts can be fully automated and interact with the rest of the system, reducing the need for operator input in the process.

- Bespoke solutions. By working with Advance you have the option of getting bespoke solutions designed by our experienced design engineers.

Pallet roller conveyor or pallet chain conveyor?

The choice between transporting your pallets on rollers or chains very much comes down to the makeup and orientation of your pallets. Standard pallets running in the correct orientation are easily transported on roller conveyors.

Twin or triple chain pallet conveyor is often used when the base of the pallet makes it unsuitable for rollers. These coneyors can be manufactured in individually driven modules to give the same level of accumulation as pallet roller conveyor.

Published: 26th May 2018