Advance installed a picking and sortation system into County Durham based online retailer Andrew James UK.

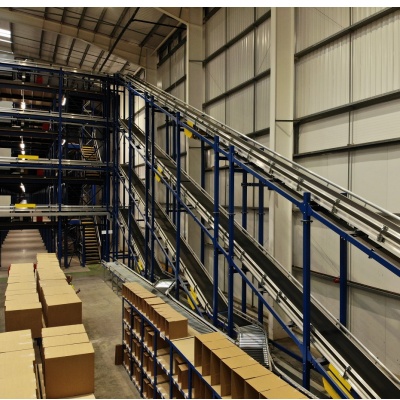

Previously based in Bowburn, County Durham, Andrew James, an award winning specialist retailer of equipment, gadgets and accessories for the kitchen, home, garden and pets, had outgrown their premises and had acquired new larger warehousing in nearby Seaham. Providing 125,000 sq ft of capacity, the new warehouse underwent a full refurbishment and fit-out programme, which included the installation of a 4-floor mezzanine structure for product distribution. With stock stored on each floor, Andrew James tasked Advance with providing an automated pick and sortation solution.

Following site surveys, Advance designed a system based on each floor having dual 70m long belt conveyors running the full length of the mezzanine. Working on each of the 4 floors, operators pick product from the shelving, apply labels and deposit items onto the belt conveyors. Product then travels onto a cross feed belt, running at 90 degrees, and on to the end of belt on that particular floor. Thereafter the product joins a decline belt conveyor, which drops down to floor level. At this point all 4 decline belt merge onto a single conveyor system - Advance’s proprietary system, their SmartLine™ roller conveyor. Being a zero line pressure conveyor, SmartLine™ offers flexibility, modular design and efficiency - ideal for tote, case and carton handling.

Once on the SmartLine™ roller conveyor, product is then taken under a barcode/label scanner. This first scanner indicates whether the product is a single order or part of a multiple order. If the latter, multiple orders are transferred off onto a loop where they are picked off to await the other items which make up a full order. Once a full order is complete it is put back onto the loop where it merges into the system with single orders. For single orders, the loop is bypassed and the product is directed to a secondary scanner which indicates the courier that the parcel is being despatched with, so it can be routed down the correct out-feed lane.

The conveyor system utilises a number of standard Advance products and services including belt conveyors, SmartLine™ Tote and Carton conveyor and bespoke control system development.

“Our working relationship with Advance Automated Systems has always been very good, they worked with us throughout the renovation and fit-out of our new distribution centre, and it was particularly helpful that they were based in the North East,” commented Andrew James UK’s managing director, Andrew Tomlinson.

“The conveying system is ideal for our requirements, moving several thousand orders per day, and was built to suit the scale of our building. We anticipate more third party clients utilising our distribution services in future and, as a result, the nature of the items we store and dispatch could change. It’s critical that we have a system in place which is flexible enough to accommodate that.”

Have a look at the video below which shows the system in action.

Make an Enquiry

Please enter your enquiry in the form below. Fields marked with a (*) are mandatory.