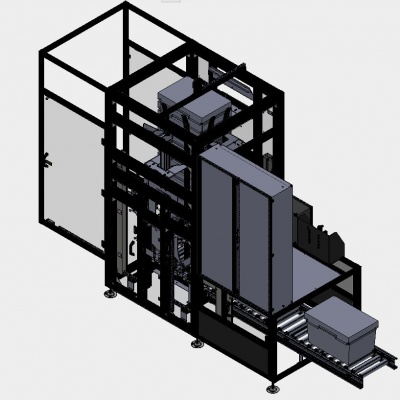

Advance Automated Systems Ltd manufacture fully automated tote stackers and de-stackers to suit a multitude of tote types, sizes, stack heights and weights. All tote stackers/destackers are manufactured and fully tested to suit the specific tote type.

Tote stackers or destackers can be used in a wide variety of industries from logistics, warehousing, manufacturing and supermarket distribution.

Advance tote stackers/de-stackers are:

- Fully automatic with a range of control options including touch screen HMI control

- Can stack or unstack totes at a rate in excess of one every 4 seconds

- Can be easily integrated into existing lines or be supplied as part of a turnkey system with our SmartLine™ roller conveyor.

- Is a low maintenance and very safe piece of equipment

Have a look at the video below showing a tote destacker being tested in our factory. This particular system is destacking stacks of 13 totes to feed the single lines back into a distribuition system. The destacker is fully automated and has been tested at a speed in excess of 1000 totes per hour.

Tote Stacker/De-Stacker Frequently Asked Questions (FAQ)

What weight can the machine handle?

Advance tote stackers/destackers have been tested with stack weights up to 50kg, if you require heavier please get in touch to discuss your application.

What speed can it run?

Throughputs and speeds can be dependent on the rate at which totes or stacks are presented to the stacker/destacker. In a production environment we have destackers operating in excess of 1000 totes per hour.

What is the limit on stack height?

Stack height obviously effects the weight of the stack but assuming the weight is not an issue then Advance stackers/destackers can be designed to suit any stack height. Please get in touch to discuss this further.

Do we have to buy a conveyor system with it?

An Advance tote stacker/destacker can be incorporated into an existing line so you do not have to buy a full conveyor system with it. The unit itself comes with a conveyor zone inside the machine and Advance can supply infeed and outfeed conveyors if required. If you have an existing conveyor line that would like to utilise then we would recommend getting in touch so we can evaluate the suitability of the line and provide a detailed proposal.

Why would I need a stacker/destacker?

There are many reasons why you may require a tote stacker/destacker, some of which may be unique to your operations. A couple of the more common reasons are space saving and time saving. Loose totes can take up a lot of room so they are often stored in stacks, it also can be quite labour intensive to stack or destack hundreds or thousands of totes which is where a tote stacker/de-stacker comes in.

Published: 3rd July 2019